Tianjin Botai Heat Exchange Equipment Co.,Ltd

Sep 17,2020

Plate heat exchanger Manufacturer: To ensure the heat exchange effect of the plate heat exchanger in Tianjin, the fundamental solution is to strengthen water quality treatment efforts, improve the water quality environment, reduce the hardness of the circulating medium, and lower the probability of Ca2+, Mg2+ combining with OH-, CO32- ions to form scale, creating a good operating environment for the heat exchanger.

Sep 21,2020

Advantages of the structure of Tianjin plate heat exchangers It has a special structure, which has obvious characteristics in heat transfer performance compared to other types of heat exchange equipment:

Oct 16,2020

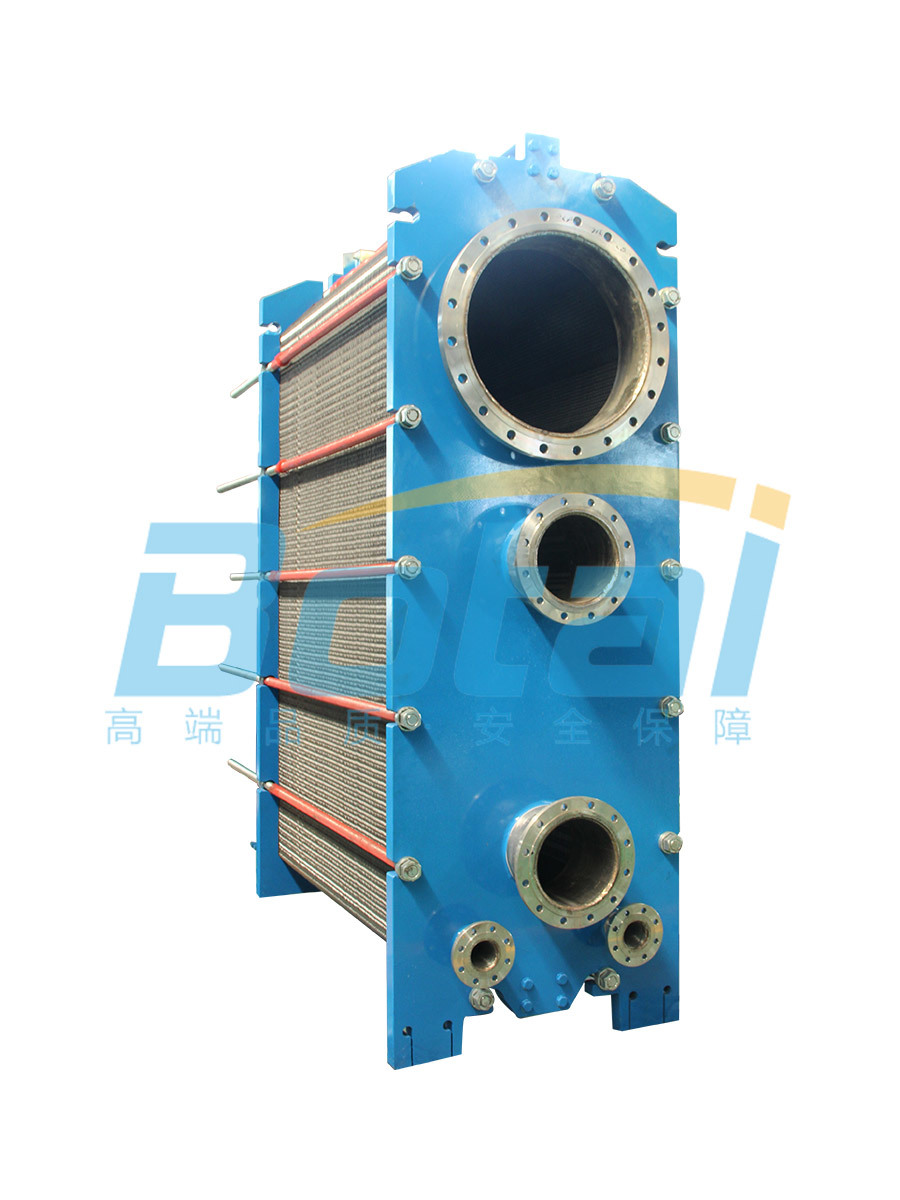

Characteristics and Case Introduction of Wide Flow Channel Plate Heat Exchanger

The wide flow channel plate heat exchanger features a unique coarse corrugated structure design, with the plate outline primarily composed of horizontal corrugations. The medium can flow unrestricted over the heat exchange surface of the plates without blockage, and it possesses high heat transfer performance that traditional tubular heat exchangers do not have.

Oct 21,2020

Manufacturer: Description of food-grade plate heat exchangers

Description of food-grade plate heat exchangers Manufacturer of plate heat exchangers: Depending on the applications, it has different names: plate heater, plate cooler, plate condenser, plate preheater;

Oct 26,2020

What industries are food-grade plate heat exchangers used in?

Application Fields Food-grade plate heat exchangers have been widely used in chemical, metallurgy, power, food, mining, petroleum, pharmaceuticals, chemical fiber, papermaking, light textile, shipbuilding, and heating sectors, and can be used in various situations such as evaporation, cooling, heating, sterilization and disinfection, condensation, and waste heat recovery.

Oct 30,2020

Plate heat exchanger Manufacturer: The design concept of food-grade plate heat exchangers

Design concept of food-grade plate heat exchangers: 1. The new flow distribution area design with pressure enhancement on the plates uses multiple channels in areas with high flow velocity to increase pressure, ensuring that the flow velocity across the entire plate is uniform, significantly improving the heat exchange efficiency of the plates, reducing dead zones, and improving the scaling condition of the plates.

Nov 02,2020

How to choose the model of a plate heat exchanger?

Selecting a plate heat exchanger is similar to most heat exchangers; it is essential to understand the inlet and outlet temperatures and flow rates of the primary side, as well as the inlet and outlet temperatures and flow rates of the secondary side. If the flow rate is unknown, it is necessary to inform the total heat transfer under the working conditions, even if the temperature is known, in order to proceed with the model selection. So, under these known conditions, how do we determine the selection of the plate heat exchanger?

Nov 03,2020

Introduction to the principles and advantages of water-water plate heat exchangers

What is a water plate heat exchanger, and what is it used for? What are the differences between it and a plate heat exchanger? I believe everyone has such questions, so let me introduce it to you in detail.

Nov 11,2020

What are the cleaning methods for water plate heat exchangers?

The cleaning of the plates in a plate heat exchanger is one of the key standards for maintaining a high thermal conductivity coefficient. Between the plates, the substance moves along the narrow and rugged flow channels. Even a thin layer of scale can cause changes in the flow channels, significantly affecting the movement of the liquid, increasing losses, and reducing the thermal conductivity coefficient. For example, a certain sugar factory used a flat stainless steel plate heat exchanger for heating, but due to poor treatment of the secondary water, the flow channels became blocked within just two months of use, rendering it unable to operate.

Nov 14,2020

Plate Heat Exchanger Company: Advantages of Water-Water Plate Heat Exchangers Heat Transfer Function Because the design of the heat transfer tubes in the water cooler is a copper tube threaded type, the total heat transfer area and the actual heat transfer effect of the water cooler are much better than that of many ordinary heat transfer tubes.