Tianjin Botai Heat Exchange Equipment Co.,Ltd

[Collection] Knowledge of Plate Heat Exchangers

2022-09-29

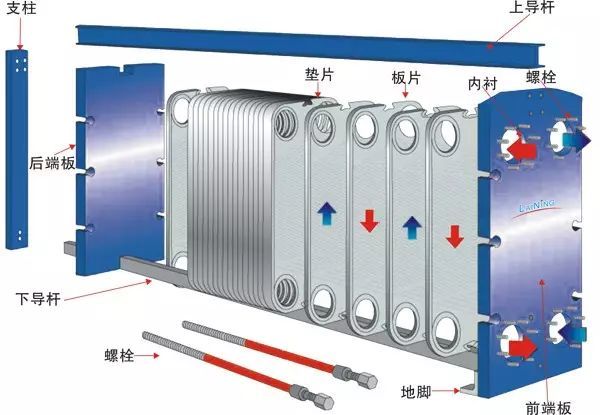

First of all, do you know what a plate heat exchanger is? How does it transfer heat? What does its structure look like? The plate heat exchanger is determined by its structural characteristics, making its installation relatively convenient and flexible. Installation of the plate heat exchanger 1. Assembly of the parts of the plate heat exchanger Regarding the assembly of the parts of the plate heat exchanger, whether the manufacturer ships the parts to the user for on-site assembly, or the user disassembles the plate heat exchanger during equipment maintenance and then reassembles it, it must be done in the following order. 1. Carefully read the accompanying documents (certificate of conformity, material certificate, flow chart, assembly drawing, and packing list, etc.). 2. Check the plates, connections.

![[Collection] Knowledge of Plate Heat Exchangers [Collection] Knowledge of Plate Heat Exchangers](https://omo-oss-image.thefastimg.com/portal-saas/pg2024070916582025431/cms/image/f342c12f-27ec-4189-bc5d-b4fc01b38e5f.jpg)

First of all, do you know what a plate heat exchanger is? How does it transfer heat? What does its structure look like?

The plate heat exchanger is determined by its structural characteristics, and its installation is relatively convenient and flexible.

1. Assembly of the parts of the plate heat exchanger

Regarding the assembly of the parts of the plate heat exchanger, whether the manufacturer ships the parts to the user unit for on-site assembly, or the user unit disassembles the plate heat exchanger during equipment maintenance and then reassembles it, it must be done in the following order.

1. Carefully read the accompanying documents (certificate of conformity, material certificate, flow chart, assembly drawing, and packing list, etc.).

2. Check whether the materials of the plates, connecting pipes, and gaskets meet the corrosion resistance requirements of the medium inside the heat exchanger.

3. Check all parts against the drawings to ensure completeness, and verify that the model and Size match the drawings.

4. Clean the gasket grooves of the plates, evenly apply adhesive, stick on the gaskets, and then neatly stack the plates together, applying a certain weight on top.

5. Assemble according to the designed flow chart and clamp in the specified order. When clamping, first tighten nuts 1, 2, 3, and 4, and then tighten nuts 5, 6, 7, 8, 9, and 10.

6. The hydraulic test should be conducted separately on each side. The test pressure is 1.25 times the design pressure of the equipment; maintain pressure for 30 minutes, and check all welded joints of the sealing boxes for leaks to qualify.

2. System installation by the user unit

The system installation by the user unit refers to the equipment sent from the manufacturer to the user unit or the equipment that has been repaired by the user unit being installed at the application station. This should be done in the following order.

1. Place the equipment on the foundation and secure the anchor bolts.

2. Check whether the cold and hot medium inlets and outlets of the pipeline match the connecting pipes on the equipment. For ease of maintenance, it is best to use short sections when connecting the pipeline to the heat exchanger.

3. Temperature gauges and pressure gauges should be installed at both the cold and hot medium inlets and outlets of the heat exchanger.

3. Precautions during the assembly of heat exchanger parts and equipment installation

1. Pay attention to the center of gravity of the equipment during hoisting.

2. When bonding gaskets in the gasket grooves, ensure that there is no sand, oil, metal shavings, or flux in the gasket and the gasket groove of the plate to avoid damaging the seal and causing leaks.

3. When tightening bolts, apply force evenly and continuously measure the distance between the inner sides of the two clamping plates to ensure that the parallelism deviation between the two clamping plates does not exceed 3mm. Clamp to the specified size and achieve the corresponding parallelism to avoid the gaskets being misaligned or slipping out of the gasket grooves. At the same time, while clamping, carefully check for any misalignment of gaskets or plates.

4. The liquid used for the hydraulic test is generally water. The water temperature should not be lower than 5°C. The pressure should be increased slowly during the test. After the test is completed, appropriately loosen the clamping nuts, drain the accumulated water, and then retighten the nuts to clamp back to the original size for future use.

5. There should be a certain amount of maintenance space around the heat exchanger, the size of which is related to the dimensions of the plates.

6. Grease should be applied to the clamping bolts, and if conditions permit, protective tubes should be fitted to prevent rust and damage to the threads.

7. If the maximum pressure at the pump outlet exceeds the maximum operating pressure of the equipment, a pressure reducing valve and a safety valve must be installed at the inlet of the equipment.

8. When the equipment is filled with liquid and under pressure, it is not allowed to tighten the nuts.

1. Start-up operation and precautions

1. When using on a new process pipeline, pay attention to eliminate debris in the pipeline to avoid blocking the heat exchanger.

2. If using wastewater as the cooling medium, or recovering waste heat from wastewater, or if the medium contains particulate solids, a filter or impurity remover should be installed at the inlet end of the heat exchanger to avoid blocking the heat exchanger.

3. When the temperature of the cooling water (being heated) exceeds 40°C, it should be softened as much as possible beforehand to avoid scaling in the heat exchanger, which affects heat transfer efficiency.

4. Check whether the pipeline connections are correct to avoid mixing two types of media, which could lead to adverse consequences.

5. Before starting, strictly check whether the inlet valves for the cold and hot media are closed and whether the outlet valves are open.

6. After completing the above tasks, the machine can be started. First, start the pumps for the cold and hot media, slowly open the inlet valve for the cold medium, and then open the inlet valve for the hot medium to allow the medium to flow slowly into the heat exchanger to avoid excessive temperature.

7. Check all sealing surfaces and all welds for any leaks or other abnormal phenomena.

8. Gradually increase the temperature while determining and calculating whether it meets the process requirements. Once satisfied, normal operation can commence.

2. Normal operation and inspection

1. Regularly check all sealing surfaces and welds of the heat exchanger for any leaks or other abnormal phenomena. If leaks are found, mark the leaking area for handling after shutdown.

2. Regularly check pressure gauges and thermometers for any abnormal phenomena.

3. When stopping, first slowly close the inlet valves for the hot and cold media, and then close the outlet valves for both media. When starting, do the opposite: first open the outlet valves, and then slowly open the inlet valves.

4. Regular testing of the low-pressure side medium is required to prevent high-pressure side medium from mixing in. If mixing occurs, it indicates an internal leak, and the operation should be stopped for handling.

3. Shutdown Operations and Precautions

1. The pump must be stopped and the power cut off before shutting down.

2. After stopping the pump, first slowly close the hot medium inlet valve, then close the cold medium inlet valve. Finally, close the outlet valves of both media.

3. If there is a vent valve installed on the pipeline, it should be opened.

4. For high-temperature and corrosive media, the equipment should be emptied as much as possible to avoid burns and corrosion when opening the equipment.

4. Diagnosis and Handling of Common Operational Failures

(1) Operating Conditions Deviate from Process Requirements

If a newly commissioned plate heat exchanger does not meet process requirements, carefully check whether the original design parameters, design calculations, and assembly are correct, and then decide whether to increase or decrease the heat exchange area, as well as change the flow combination.

If the plate heat exchanger starts operating normally but deviates from process requirements after a period of operation, such as an increase or decrease in pressure drop; an increase or decrease in medium outlet temperature.

The method to handle this fault is:

1. Check whether the inlet parameters of the cold and hot media match the original design values. If they do not match, efforts should be made to adjust them to the original design values. If the inlet parameters have changed and cannot be adjusted to the original design values, a redesign calculation should be performed to decide whether to increase or decrease the heat exchange area or change the flow combination.

2. If the inlet parameters of the cold and hot media match the original design values, but the outlet parameters do not meet the design values, the operation should be stopped, and the plates should be disassembled to check for blockages or scaling between the plates, and timely handling should be performed.

(2) Leakage Phenomenon in Plate Heat Exchangers

Due to the long sealing perimeter of the plate heat exchanger and the thin plates, leakage may occur during use. Leakage can be divided into internal and external leakage.

1. External Leakage of the Plate Heat Exchanger

This refers to the leakage of the medium inside the plate heat exchanger to the external space. This type of leakage is generally easy to detect. The main causes of this leakage are aging, corrosion of the gaskets, or deformation of the plates. When this leakage occurs, the leaking part should be marked, and the equipment should be opened to replace the gaskets or plates.

2. Internal Leakage of the Plate Heat Exchanger

This refers to the leakage of high-pressure side medium to the low-pressure side due to some reason within the heat exchange equipment. This type of leakage is generally not easy to detect in a timely manner. The main causes of this leakage are perforation, cracks, and corrosion of the plates. The method to detect this leakage is to regularly test the medium on the low-pressure side and judge from the changes in its composition.

The method for checking this leakage during shutdown is:

(1) Disassemble the plate heat exchanger, clean the dirt on the surface of the plates, dry them, and then reassemble the heat exchanger. Conduct a water pressure test on one side at a pressure of 0.2~0.3Mpa. Stop the test when water flows out from the other side, open the heat exchanger, and carefully observe the untested side of the plates, where the wet plates indicate those with holes or cracks.

(2) A translucent and colored inspection method can also be used on-site to identify defective plates. All identified defective plates and gaskets must be replaced, and the equipment should be reassembled for use.

(3) Misalignment of Plates in the Plate Heat Exchanger

For plate heat exchangers with significant changes in medium flow and pressure, and which are multi-stage combinations used for a long time, misalignment of plates is likely to occur. After misalignment, external leakage may occur quickly; some may not immediately leak externally, but they pose a hidden danger of leakage, so they must be handled promptly.

The main causes of misalignment are: deformation of the heat exchanger plates; the sealing gaskets of the plate heat exchanger sliding out of the gasket groove. To handle this misalignment, the deformed plates and gaskets that have slid out of the groove should be replaced in a timely manner.

(4) Simple Handling Methods for Plate Heat Exchangers When Repair Equipment is Lacking On-Site

During the use of plate heat exchangers, whether the plates are deformed, cracked, or perforated, or the gaskets are aging or broken, timely replacement is required. If there are not enough spare parts on-site, and the heat exchange equipment has no backup units and cannot be shut down, simple on-site handling should be performed.

The simple on-site handling method is to pair the damaged plates and leaking plates (A plate + B plate). If the quantity is not too large and the number of reduced flow paths is also not too many, they can be reassembled and continue to be used, which will not have a significant impact on production.

In addition to repairs under special circumstances, plate heat exchangers should also undergo regular maintenance. Due to the ease of disassembly and maintenance of plate heat exchangers, special tools and equipment are generally not required. Different methods can be used depending on the situation. If the equipment has not leaked and only the heat transfer system K has decreased, the heat exchanger can be maintained without disassembly, by using a closed-loop system to circulate descaling liquid into the equipment for several hours. If such conditions are not available on-site, and if it is found that scaling is not too severe after disassembling the equipment, the plates can be rinsed directly with water without removing them, while using a soft brush for cleaning.

1. Normal Operation Maintenance

1. Equipment that needs maintenance should be disassembled in reverse order of installation.

2. Equipment used in the petroleum and chemical industries should undergo regular maintenance according to the maintenance cycle.

3. If the medium inside the equipment is flammable, explosive, or highly corrosive, maintenance should be performed at least once a year.

4. For plate heat exchangers used in other industries, if no leakage has occurred, it is best to perform maintenance once every three years.

2. Cleaning and Protection of Plates

Keeping the plates clean is one of the important conditions for maintaining a high heat transfer coefficient. Between the plates, the medium moves along narrow and winding channels. Even a not very thick layer of scale can cause changes in the channels, significantly affecting the movement of the fluid, increasing pressure drop, and reducing heat transfer coefficient. For example, a sugar factory used a plate heat exchanger for heating, and due to poor treatment of the secondary water, the entire channel was blocked within just two months of use, making it unable to continue operation.

1. Chemical cleaning method

This method involves circulating a chemical solution through the heat exchanger to dissolve and discharge the dirt on the surface of the plates. This method does not require disassembling the heat exchanger, simplifying the cleaning process and reducing the labor intensity of cleaning. Since the corrugation of the plates can promote intense turbulence of the cleaning liquid, which is beneficial for dissolving the scale, the chemical cleaning method is a relatively ideal method.

2. Mechanical (physical) cleaning method

This method involves manually scrubbing the plates with a brush after disassembling them to achieve the purpose of cleaning the dirt on the surface of the plates. Although this method is more direct, it is not easy to clean hard and thick scale thoroughly.

3. Comprehensive cleaning method

For cases where the scale is relatively hard and thick, it is difficult to clean thoroughly using only one of the above methods. The comprehensive method first uses the chemical cleaning method to soften the scale, and then uses the mechanical (physical) cleaning method to remove the scale, in order to keep the surface of the plates clean.

4. Precautions during cleaning

(1) During chemical cleaning, the solution should maintain a certain flow rate, generally 0.8-1.2 m/s. The purpose is to increase the turbulence of the solution.

(2) Different cleaning solutions should be used for different types of dirt. In addition to frequently using diluted soda solution, a 5% nitric acid solution can be used for water scale. For scale generated during soda production, a 5% hydrochloric acid solution can be used. However, chemical cleaning agents that corrode the plates must not be used.

(3) During mechanical (physical) cleaning, it is not allowed to use carbon steel brushes to scrub stainless steel plates to avoid accelerating the corrosion of the plates. At the same time, care must be taken not to scratch or deform the surface of the plates.

(4) The plates after cleaning should be rinsed with clean water and dried, and care should be taken to prevent deformation of the plates during storage.

3. Characteristics of gaskets and their replacement

As the application fields of plate heat exchangers continue to expand, there are different requirements for temperature resistance, pressure resistance, and corrosion resistance for different media and processes. It is obviously impossible to use a "universal" gasket to adapt to all situations, and different materials of gaskets should be used for different situations. The commonly used cross-sectional shape of gaskets is hexagonal. Common types of gaskets include natural rubber, neoprene rubber, nitrile rubber, EPDM rubber, silicone rubber, fluorine rubber, and asbestos fiber boards.

If the gaskets of the plate heat exchanger show leakage, breakage, aging, etc. during use, they should be replaced in a timely manner. The replacement should be carried out in the following order.

1. Remove the old gaskets. Care should be taken during disassembly to avoid scratching the gasket groove.

2. Use acetone, butanone, or other ketone solvents to remove the residual glue in the gasket groove.

3. Wipe the gasket groove and gaskets with a clean cloth or cotton yarn.

4. Evenly apply adhesive in the gasket groove.

5. Stick the clean new gasket onto the plate.

6. The plate with the properly attached gasket should be placed in a flat, cool, and ventilated place to naturally dry for 4 hours before it can be installed and used.

The article comes from the internet. If there is any infringement, please contact to delete.

Next page: