Tianjin Botai Heat Exchange Equipment Co.,Ltd

Share

Details

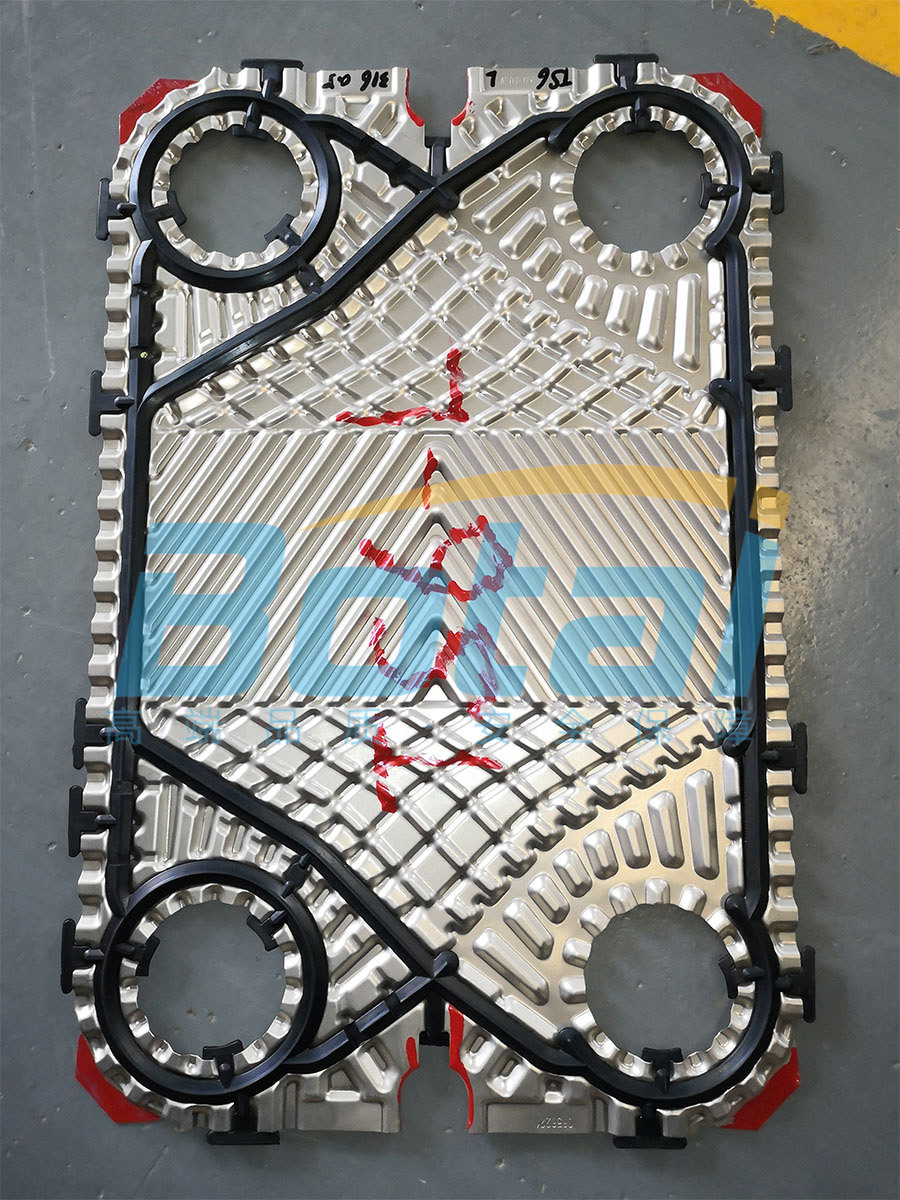

Plateis an important component of plate heat exchangers, mainly used to isolate the medium and conduct heat exchange. Its main materials include stainless steel (304/304L, 316/316L, 254SMO), titanium, nickel, titanium-palladium alloy, Hastelloy, etc.

1. Composition of the plate: Each plate consists of two components.

1) Metal plate: The metal plate is a thin metal sheet that is pressed with corrugations, sealing grooves, and corner holes, and is an important heat transfer component. The corrugations not only enhance heat transfer but also increase the rigidity of the thin plate, thereby improving the pressure-bearing capacity of the plate heat exchanger. It can also promote the liquid to flow turbulently, thus reducing the formation of sediments or dirt, playing a certain "self-cleaning" role.

2) Sealing gasket: Installed in the groove around the plate, sealing the periphery between the plates to prevent fluid leakage (click to view the reasons and methods for external leakage of plate heat exchangers), and according to design requirements, sealing part of the corner holes, allowing hot and cold media to flow according to their own channels.

2. Production of the plate:

Plates are all formed by a single stamping process using molds. Only plates formed in one go can have the same precision, so there is uniform metal point contact between the plates, ensuring that the plate heat exchanger can operate normally under high pressure and withstand the pressure shocks of the system.

Plate heat exchanger gasketsare relatively complex polymer systems, usually composed of different components such as rubber polymers, vulcanizing agents, fillers, anti-aging agents, processing aids, and diluents. Although processing aids cannot extend the lifespan of rubber gaskets, they are very effective in improving the mixing, extrusion, and molding functions during the gasket manufacturing process. The selection of raw materials and their ratios will determine the final performance of the rubber gasket.

Among these, natural rubber is obtained from the latex of the rubber tree, with a basic chemical composition of polyisoprene; isoprene rubber is a high-cis rubber made from isoprene, and due to its structure and properties being similar to natural rubber, it is also called synthetic natural rubber; styrene-butadiene rubber is made from the copolymerization of butadiene and styrene, and is divided into emulsion polymerized styrene-butadiene rubber and solution polymerized styrene-butadiene rubber based on the production method.

Cis-butadiene rubber is obtained by the polymerization of butadiene. Compared to other general-purpose rubbers, the vulcanized cis-butadiene rubber has particularly excellent cold resistance, wear resistance, and elasticity, generates less heat under dynamic load, has good aging resistance, and is easy to blend with natural rubber, chloroprene rubber, nitrile rubber, etc.

Previous Page:

Next page:

TS6-L

Classification:

Key words:

Messages

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!

Related Products