Tianjin Botai Heat Exchange Equipment Co.,Ltd

How to choose the model of a plate heat exchanger?

2020-11-02

Selecting a plate heat exchanger is similar to most heat exchangers; it is essential to understand the inlet and outlet temperatures and flow rates of the primary side, as well as the inlet and outlet temperatures and flow rates of the secondary side. If the flow rate is unknown, it is necessary to inform the total heat transfer under the working conditions, even if the temperature is known, in order to proceed with the model selection. So, under these known conditions, how do we determine the selection of the plate heat exchanger?

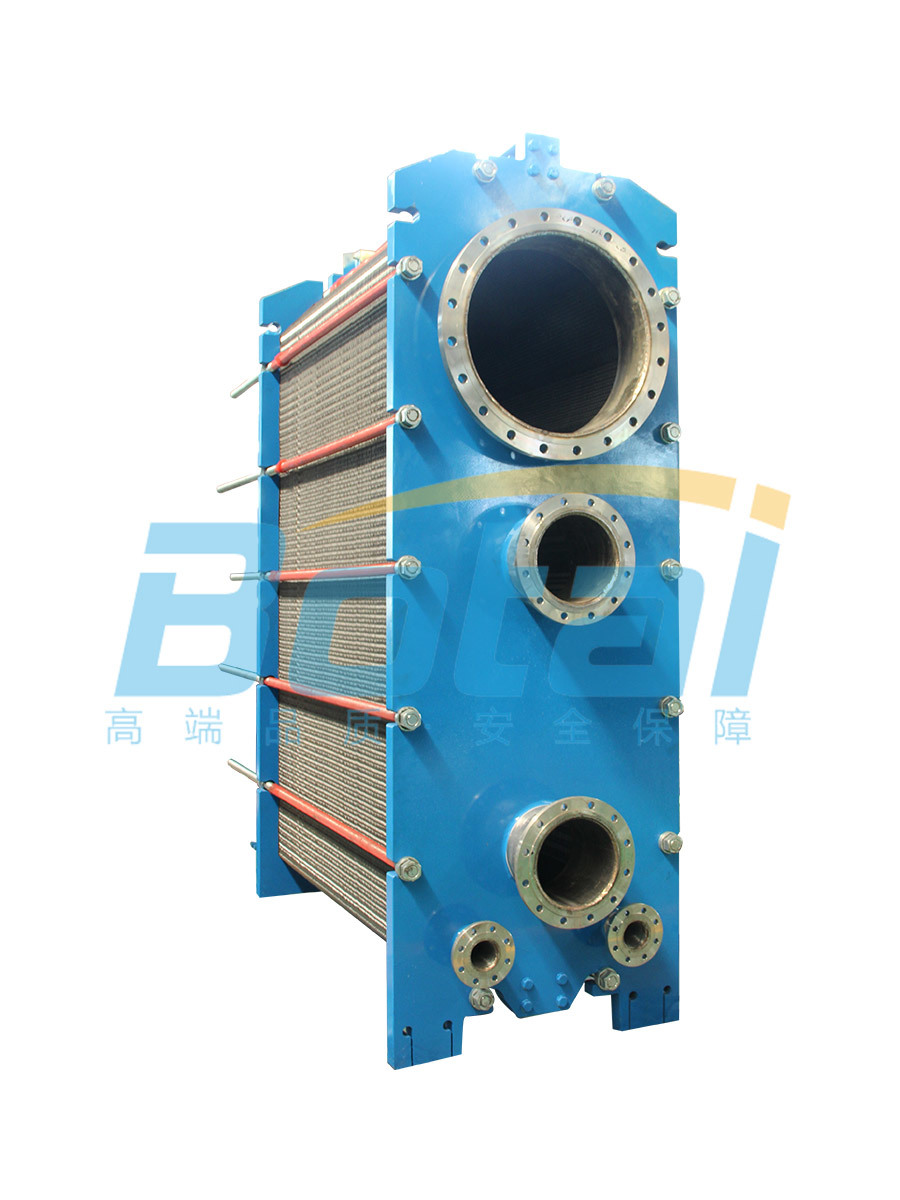

Water-water plate heat exchangerLike most heat exchangers, it is essential to understand the inlet and outlet temperatures and flow rates of the primary side, as well as the inlet and outlet temperatures and flow rates of the secondary side. If the flow rate is unknown, it is necessary to inform the total heat transfer under the working conditions based on the temperature. Then, under the known conditions, how do we determine the selection of the plate heat exchanger? Today, I will introduce it to everyone.

Selection of water-water plate heat exchanger

Pressure drop verification

In the design and selection of plate heat exchangers, there are generally certain requirements for losses, so verification is conducted. If the verified loss exceeds the allowable loss, the design and selection calculations need to be redone until the process requirements are met.

Plate type selection

The type or corrugated pattern of the plates should be determined based on the specific needs of the heat transfer site. For situations with large flow rates and small allowable losses, a plate shape with low friction resistance should be used, and vice versa for high friction resistance. Depending on the liquid pressure and temperature, it should be determined whether to choose a removable type or a welded type. When determining the plate shape, it is not suitable to choose plates with a very small double plate area to avoid excessive plate numbers, small flow rates between plates, and low thermal conductivity, especially for large plate heat exchangers.

Selection of flow paths

The flow path refers to a series of connected flow channels in the same flow direction of a substance within the heat exchanger, where the flow channels are formed by adjacent plates in the plate heat exchanger. Generally, several flow channels are connected in series or parallel to create different combinations of cold and hot substance flow paths.

Selection of channels

The composition method of the flow paths should be determined based on heat transfer and liquid friction resistance calculations, considering the requirements of the process standards. It is preferable to make the convective heat transfer coefficients in the cold and hot flow paths the same or close to each other to achieve better heat conduction results. When the convective heat transfer coefficients on both sides of the heat transfer surface are the same or close, the thermal conductivity reaches a large value. Although the flow rates between the plates of the heat exchanger are not the same, the calculations for heat transfer and liquid friction resistance are still based on the average flow rate.

The above is the introduction to the selection.Water-water plate heat exchangerIf you have any questions, feel free to consult the website customer service.

Previous Page: