Tianjin Botai Heat Exchange Equipment Co.,Ltd

Introduction to the principles and advantages of water-water plate heat exchangers

2020-11-03

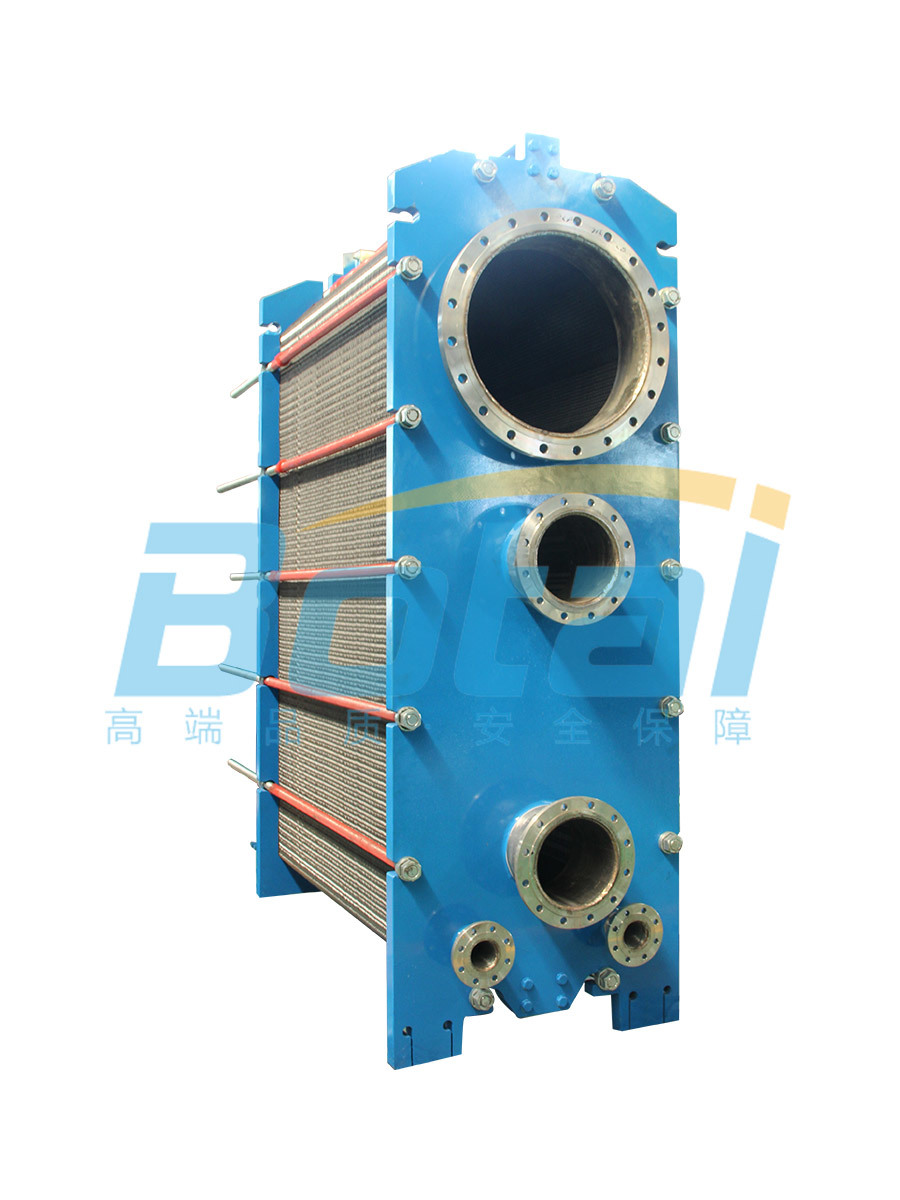

What is a water plate heat exchanger, and what is it used for? What are the differences between it and a plate heat exchanger? I believe everyone has such questions, so let me introduce it to you in detail.

Water-water plate heat exchangerWhat is it, and what does it do? What are the differences compared to plate heat exchangers? I believe everyone has such doubts, so let me introduce it to you in detail.

I. Basic Operating Principle

It mainly uses high-temperature water to heat ultra-low temperature water, through a series of wavy copper plates stacked in a plate heat exchanger, conducting heat exchange through the thin rectangular channels formed between each plate. This is the general heat transfer process.

II. Applications

The application of water-water plate heat exchangers is mainly in boiler installations, exchanging heat between the boiler water and the heating supply network water. After the exchange between the primary and secondary sides, the primary side circulates back to the boiler, while the secondary side reaches the end customers through a centrifugal pump, eliminating the need for heating at normal temperatures, thus saving energy.

It is also present in centralized heating in residential communities, as the heating boiler often suffers from corrosion, leading to scaling or leaks. After installing the exchanger, the water circulation can be divided into internal and external cycles, effectively reducing the entry of dirt or corrosive substances into the boiler, minimizing scaling, and ensuring water quality. Therefore, the exchanger plays a crucial role in centralized heating in residential communities.

III. Advantages

1. Fast heat conduction

The plate heat exchanger consists of several plates, with a thickness of 0.5 mm, allowing for efficient heat convection. Especially in lubricated conditions and boiler systems, it can instantly reach the desired temperature, as the thermal conductivity can reach 5000W/(m2.℃), solving energy consumption issues and saving costs, which cannot be achieved by boiler heating.

2. Increased boiler lifespan

Since boilers are prone to scaling, they often need to be replaced, which not only incurs costs but also fails to achieve the desired processing effect. The lubricated plate heat exchanger can convert most of the heat, and while the lubricated plate heat exchanger may also experience scaling, the plates can be disassembled and cleaned, thus extending their lifespan!

3. Low energy consumption

As mentioned in the article, after the exchange between the primary and secondary substances, the secondary side reaches the customer, and the primary side goes to the boiler. Therefore, when heating again, there is no need to heat at normal temperatures, addressing energy consumption issues.

That is the detailed explanation.Water-water plate heat exchangerIf you have any questions, you can consult customer service.

Previous Page: