Tianjin Botai Heat Exchange Equipment Co.,Ltd

Share

Fully welded plate heat exchanger

Classification:

Key words:

Details

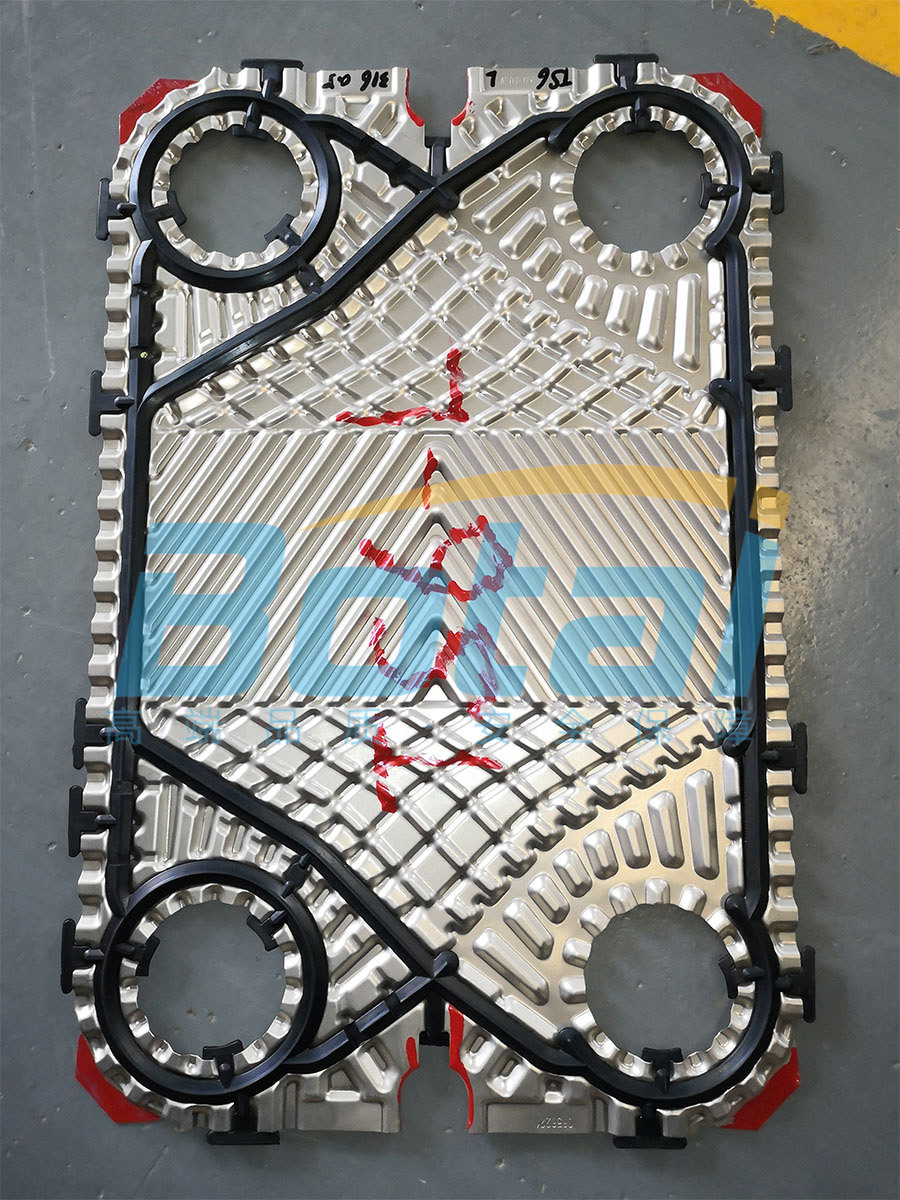

Plate and shell heat exchangerIt is a heat exchanger that uses plate tubes as the heat transfer element, also known as a plate heat exchanger. It mainly consists of a plate tube bundle and a shell (as shown in the figure). The contact points of the paired plates, which are cold-formed, are tightly welded together to form a plate tube containing multiple flat flow channels. Many plate tubes of varying widths are arranged in a specific order. To maintain the spacing between the plate tubes, metal strips are embedded at both ends of adjacent plate tubes and welded to the plate tubes. The ends of the plate tubes form tube sheets, thereby securely connecting many plate tubes together to form a plate tube bundle. The end face of the plate tube bundle presents several flat flow channel plate tube bundles assembled within the shell, and it eliminates longitudinal expansion differences through sliding seals with the shell. The cross-section of the equipment is generally circular, but there are also rectangular, hexagonal, etc. Fluid A flows inside the plate tubes, while fluid B flows between the plate tubes inside the shell.

The plate and shell heat exchanger is a structural form that lies between the shell and tube heat exchanger and the plate heat exchanger, combining the advantages of both:

① The plate serves as the heat transfer surface, providing good heat transfer efficiency. The heat transfer coefficient is about twice that of the shell and tube heat exchanger.

② Compact structure and small volume.

③ Temperature and pressure resistant, with a maximum working temperature of up to 800℃ and a maximum working pressure of 6.3 MPa.

④ The fluid flows at high speed in the flat flow channels, and the plate surface is smooth, making it difficult to scale. The plate bundle can be disassembled for easy cleaning. However, the manufacturing process of this heat exchanger is more complex than that of the shell and tube heat exchanger, with a large amount of welding required and high standards, thus limiting its widespread application. The plate and shell heat exchanger is used in industrial sectors such as chemical, papermaking, pharmaceuticals, and food. Typical products are mainly used in processing industries such as food and pharmaceuticals, where good heat transfer efficiency and short residence time are required.

Previous Page:

Next page:

Fully welded plate heat exchanger

Classification:

Key words:

Messages

If you are interested in our products, please leave your contact information, we will contact you as soon as possible, thank you!

Related Products